vickers hardness test lab report|how to calculate vickers hardness : consultant Vickers Hardness Test. The Vickers hardness test was developed by RL. Smith and Sandland in 1921 at Vickers Ltd as an alternative to brinell hardness test method to measure the hardness of the material. Resultado da sexta-feira, 22 de dezembro de 2023. Um homem foi alvejado por disparos de arma de fogo na noite desta quinta-feira (21), no município de Bom .

{plog:ftitle_list}

WEBCompatible Wire Gauge (AWG) 23-24. Color. Clear. Standards Met. Exceeds ANSI/TIA Category 6A and ISO Class EA performance requirements when properly terminated to .

The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess . The advantages of the Vickers hardness test is the extremely accurate readings can be taken and just one type of indenter is used for all . (I) Aim: To determine the hardness of the given Specimen using Vickers hardness test.Vickers Hardness Test. The Vickers hardness test was developed by RL. Smith and Sandland in 1921 at Vickers Ltd as an alternative to brinell hardness test method to measure the hardness of the material.

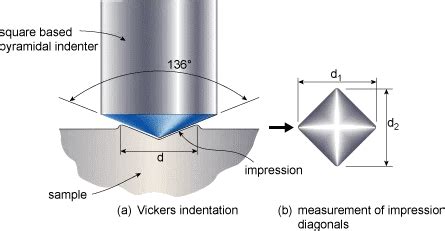

Vickers hardness should be reported like 800 HV/10, which means a Vickers hardness of 800, was obtained using a 10 kgf force. The advantages of the Vickers hardness test are that .Vickers hardness test requires a diamond pyramid indenter with an included angle of 136o. This technique is also called a diamond pyramid hardness test (DPH) according to the shape of .

The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees .VICKERS HARDNESS TEST Aim: To determine the Vickers hardness of hard materials such as hardened steel and moderately hard materials such as brass, copper and aluminium. Theory: .

vickers hardness testing procedure

Static indentation tests are one way to determine hardness. For static indentation, a cone, pyramid, or ball is forced into the surface of the material. The relationship between the load applied for a given length of time and the area .Rockwell hardness test. Use ASTM E 140-88 "Standard Hardness Conversion Tables for Metals (Relationship Between Brinell Hardness, Vickers Hardness, Rockwell Hardness, Rockwell .How to use the Rockwell hardness test for quick hardness testing in the lab or production environment. Vickers Hardness testing (HV) . The Vickers hardness test is often regarded as easier to use than other hardness tests: .

lab report vickers hardness testing name class number matric. muhammad affan akmal bin abdul rahman. dkm 3d 08dkm21f. mohamad hakimi bin rosmawi. dkm 3d 08dkm22f. muhammad syamir roshdan bin saipuddin. dkm 3d .

Material Testing Lab 18MEL37A/47 A Dept. of Mechanical Engg, Atria Institute of Technology Bengaluru Page 3 . The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative . 5. PAGE 4 Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a test force of between 1gf and 100kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the .Torsion Test LAB Report; Torsion TEST lab 3 strenght lab; Effect OF HEAT Treatment experiment material lab; Related documents. MEC 424 - Laboratory 1 - LAB . Advantage of Vickers hardness test is are that very accurate readings can be taken and just one type of indenters used for all type of metals and surface treatments. Also, its very .In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the sample is measured using a microscope.

Bogazici University Materials Science Course - Hardness Tests Lab Report. . The Vickers hardness test utilizes a diamond pyramid shaped indenter that is ground in the form of a squared pyramid with an angle of 136o between faces, and the depth of indentation is about 1/7 of the resulting impressions diagonal length. .Data and Results: Table 1: Vickers Hardness Raw Data. Vickers Hardness Testing Lab. Material. Vickers Indentation Size for 30 kg Indentation Load Average HV 1st test 2nd test 3rd test d1 ± δ1 d2 ± δ2 d1 ± δ1 d2 ± δ2 d1 ± δ1 d2 ± δ2 d ± δ HV ± δ 6061-T6 Aluminum 735 724 747 728 734 103 1018 Cold Rolled Steel. 444 555 480 469 487 235To ensure our progression in quality assurance, ATS’s Vickers Hardness Testing procedures abide by the ASTM E92 and ASTM E384 standards, for which we maintain ISO 17025 (A2LA) accreditation.

PRACTICAL HARDNESS TESTING MADE SIMPLE Table of Contents Page 1. GENERAL 1 2. INTRODUCTION 3 3. BRINELL HARDNESS TESTING 9 4. VICKERS HARDNESS TESTING 14 5. ROCKWELL HARDNESS TESTING 17 6. INFORMATIONS 22 i PRACTICAL HARDNESS TESTING MADE SIMPLE 1. GENERAL Important facts and features to be known and .The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small parts, thick coatings and materials with low hardness. . DuraScan micro hardness tester Vickers laboratory hardness tester – from manual to fully automatic. Test methods. Vickers; Knoop; Brinell; Test load. 0.00025 – 62.5 kgf;lab report 03 materials engineering experiment no. 02 rockwell hardness test of given sample introduction: hardness of material is generally defined as. Skip to document. . The hardness test is a mechanical test for material properties which are used in engineering design, analysis of structures and material development. .

Introduction to Vickers Hardness Test The Vickers hardness test, developed in 1921 by Robert L. Smith and George E. Sandland of Vickers Ltd., provides an alternative to the Brinell hardness test with a simpler scale. While it can be used to test the hardness of metals and other hard materials, its main focus is on [.]

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

The LAB: Vickers hardness testing of various materials Samples (in inches) 6061-T6 Aluminum (½ x ½ x 1½) 1018 Cold Rolled Steel (½ x ½ x 1½) Half Hard Brass Alloy 360 (½ x ½ x 1½) 110 Copper (1 x 0 x 5) Zirconia (ZrO 2 ) ceramic15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were performed on the cross-section surfaces of the rolled strips along the . What is the Vickers Hardness Test. NextGen explains the machine, its applications and the necessary consumables required for the Vickers Hardness Testing needs. Home; Products. Special Offers. . The .

Dr. S. E. Beladi, PE Mechanics of Materials Lab P a g e | 1 Experiment Five- Principals of Stress and Strains Test Experiment Six (6) Hardness Testing Introduction . Vickers hardness test requires a diamond pyramid indenter with an included angle of 136o. This technique is also called a diamond pyramid hardness test (DPH) according to the .Guidelines for students for report preparation 14. Lab assessment criteria 15. Details of Conducted Experiments 16. Lab Experiments . Strength of Material Lab (LC-ME 214G) . To study the Vickers hardness testing machine & perform the Vickers hardness test. 4. To study the Erichsen sheet metal testing machine & perform the Erichsen sheet metal .

vickers hardness testing machine price

The Vickers hardness number (HV) is calculated based on the indentation diagonal lengths. This method is suitable for a wide range of materials, including metals, ceramics, and plastics. Due to its small indentation size the Vickers hardness test allows for testing on very thin materials and provides accurate results. Where: HV is the Vickers .

The Vickers method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6507, ASTM E92, ASTM E384).Vickers Hardness Test – micro and macro hardness with applied loads from 25 grams to 50 kilograms; Knoop Hardness Test – applied loads from 25 grams to 2 kilograms; Test samples up to 5.5” in diameter and 10″ in height; Surface Contamination; Carburization & Decarburization; Case Depth; Profiles, including Welds1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness testing machines (Part B), and the calibration of standardized hardness test blocks (Part C). Two general classes of standard tests are recognized:

Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding Loads. Method Load Range Standard; Method. Brinell. Load Range. 1 kgf–3,000 kgf. Standard. ASTM E10, ISO 6506. Method.In the Vickers hardness testing method, the hardness is measured by the load applied over the area of impression. The Vickers indenter is a square pyramid 136° angles between opposite site. The Vickers hardness number or (HV) are found from the following formulas: HV = Load/Impression Area HV= 2 𝐹 sin (𝜃 2 ) × 1000 𝑑 2 = 1 × 𝐹 .

DJJ30113 LAB SHEET LAB 3 Vickers Hardness Test (1) - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. This document provides instructions for performing a Vickers hardness test. It describes the equipment needed, including a Vickers hardness machine with an indenter and microscope. It explains that the test involves .The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. . REPORT In your laboratory reports must have the followings; a) Cover b) A short introduction

Lab-Potcher service

vickers hardness testing machine diagram

Em Motel - Acompanhantes em Luziânia - GO

vickers hardness test lab report|how to calculate vickers hardness